Buying Guide for the Best Table Saw Blades

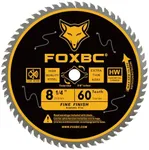

Choosing the right table saw blade is crucial for achieving the best results in your woodworking projects. The right blade can make a significant difference in the quality of your cuts, the efficiency of your work, and the longevity of your equipment. When selecting a table saw blade, consider the type of material you will be cutting, the type of cuts you need to make, and the precision required for your projects. Here are some key specifications to consider when choosing a table saw blade.Blade DiameterBlade diameter refers to the size of the blade, typically measured in inches. Common diameters include 8, 10, and 12 inches. The diameter of the blade determines the depth of the cut it can make. Larger diameters can cut through thicker materials, while smaller diameters are suitable for thinner materials. Choose a blade diameter that matches the capacity of your table saw and the thickness of the materials you plan to cut.

Number of TeethThe number of teeth on a saw blade affects the smoothness and speed of the cut. Blades with more teeth (e.g., 60-100) produce smoother cuts and are ideal for fine woodworking and cutting hardwoods. Blades with fewer teeth (e.g., 24-40) cut faster and are better for rough cuts and cutting softwoods. Consider the type of cuts you need to make and the material you are working with when choosing the number of teeth.

Tooth ConfigurationTooth configuration refers to the shape and arrangement of the teeth on the blade. Common configurations include ATB (Alternate Top Bevel), FTG (Flat Top Grind), and TCG (Triple Chip Grind). ATB blades are versatile and provide clean cuts in both crosscuts and rip cuts. FTG blades are designed for ripping and provide fast, rough cuts. TCG blades are ideal for cutting hard materials like laminates and plastics. Choose a tooth configuration based on the type of cuts and materials you will be working with.

Kerf WidthKerf width is the thickness of the cut made by the blade. Thin kerf blades remove less material, resulting in less waste and requiring less power from the saw. They are ideal for portable and lower-powered saws. Full kerf blades are thicker and more durable, making them suitable for heavy-duty cutting and high-powered saws. Consider the power of your table saw and the importance of material conservation when choosing the kerf width.

Blade MaterialBlade material affects the durability and performance of the blade. Common materials include high-speed steel (HSS), carbide-tipped, and diamond-tipped. HSS blades are affordable and suitable for general-purpose cutting but wear out faster. Carbide-tipped blades are more durable and maintain their sharpness longer, making them ideal for frequent use and cutting hardwoods. Diamond-tipped blades are extremely durable and used for cutting very hard materials like stone and tile. Choose a blade material based on the frequency of use and the hardness of the materials you will be cutting.

Hook AngleHook angle is the angle of the teeth relative to the center of the blade. Positive hook angles (teeth leaning forward) provide aggressive cuts and are suitable for ripping. Negative hook angles (teeth leaning backward) provide smoother cuts and are ideal for crosscutting and cutting materials like plywood and laminates. Neutral hook angles are versatile and can be used for both ripping and crosscutting. Consider the type of cuts you need to make and the materials you will be working with when choosing the hook angle.