Buying Guide for the Best Refrigerant Leak Sealer

Choosing the right refrigerant leak sealer is crucial for maintaining the efficiency and longevity of your HVAC system. A refrigerant leak sealer is used to seal small leaks in the refrigerant lines of air conditioning and refrigeration systems. When selecting a refrigerant leak sealer, it's important to consider several key specifications to ensure you get the best fit for your needs. Understanding these specifications will help you make an informed decision and keep your system running smoothly.CompatibilityCompatibility refers to whether the leak sealer can be used with the type of refrigerant in your system. This is important because using an incompatible sealer can cause damage to your HVAC system. Refrigerant leak sealers are typically designed to work with specific types of refrigerants, such as R-22, R-410A, or R-134a. To choose the right one, check the type of refrigerant your system uses and ensure the sealer is compatible with it. If you are unsure, consult your system's manual or a professional technician.

Leak SizeLeak size refers to the size of the leaks that the sealer can effectively repair. This is important because not all sealers can handle all leak sizes. Some sealers are designed for very small leaks, while others can handle larger ones. Typically, leak sealers are categorized by the size of the leak they can seal, such as micro-leaks, small leaks, or larger leaks. To pick the right one, identify the size of the leak in your system. If the leak is very small, a micro-leak sealer will suffice. For larger leaks, choose a sealer that specifies it can handle those sizes.

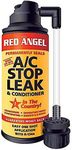

Application MethodThe application method refers to how the sealer is introduced into the HVAC system. This is important because different methods may be more suitable for different systems or user preferences. Common application methods include aerosol cans, injectors, and liquid additives. Aerosol cans are often the easiest to use and are suitable for small systems. Injectors provide a more controlled application and are ideal for larger systems. Liquid additives are mixed with the refrigerant and are suitable for ongoing maintenance. Choose the method that you are most comfortable with and that suits your system's requirements.

LongevityLongevity refers to how long the sealer will last once applied. This is important because a longer-lasting sealer will provide more durable repairs and reduce the need for frequent reapplications. Some sealers are designed to provide a temporary fix, while others offer a more permanent solution. To choose the right one, consider how long you need the repair to last. If you need a quick, temporary fix, a short-term sealer will do. For a more permanent solution, look for a sealer that promises long-lasting results.

Environmental ImpactEnvironmental impact refers to how the sealer affects the environment. This is important because some sealers contain chemicals that can be harmful to the environment. Environmentally friendly sealers are designed to minimize their impact and are often made from non-toxic, biodegradable materials. To choose the right one, consider the environmental regulations in your area and your personal preference for eco-friendly products. Opt for a sealer that is labeled as environmentally safe if this is a priority for you.