Best Drill Bits

From leading brands and best sellers available on the web.

DEWALT

33%OFF

DEWALT Drill Bit Set, 21-Piece, 135 Degree Split Point, 31 Degree Helix, Black Oxide Coated, For Plastic, Wood and Metal (DWA1181)

DEWALT

17%OFF

DEWALT Titanium Nitride Coated Drill Bit Set, Pilot Point, 21-Piece (DW1361)

DEWALT

24%OFF

DEWALT Drill Bit Set, 14-Piece, 135 Degree Split Point, For Plastic, Wood and Metal (DWA1184)

BOSCH

BOSCH CO14B 14-Piece Assorted Set with Included Case - Cobalt M42 Metal Drill Bits with Three-Flat Shank for Drilling Applications in Stainless Steel, Cast Iron, Titanium, and Light-Gauge Metal

COMOWARE

COMOWARE Titanium Twist Drill Bit Set - 16 Pcs Hex Shank High Speed Steel for Wood Plastic Aluminum Alloy, Quick Change, 1/16"-1/4"

IRWIN

IRWIN Tools Hanson Screw Extractor and Drill Bit Set, 35 Piece, 11135ZR

Milwaukee

Milwaukee 48-89-4672 Impact Duty Titanium Drill Bit Set (29 Piece)

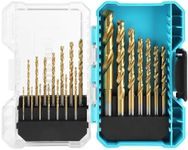

Makita

Makita B-65399 Impact Gold 14 Pc. Titanium Drill Bit Set, 1/4 In. Hex Shank

Milwaukee

20%OFF

Milwaukee 48-89-4680 18-Piece Shockwave Impact Duty Thunderbolt Titanium Drill Bit Set w/Anti-Walking 135 Degree Angled Tip and Storage Case

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Most Popular Categories Right Now